Thoughts From the Swiss Trip, Part I

Home from an epicenter of watchmaking... and I can't wait to go back.

I had a lot of ideas.

Going to Switzerland for the first time, I wanted to do a lot, see a lot, and maybe score a couple of visits to brands I happen to respect a lot. I wanted to see the Patek museum, hit the Cité du Temps in Biel (HQ to the Swatch group and the home of the Omega museum), swing by the MB&F gallery, do an Oris factory visit, and find time to roam the streets of Geneva and Zurich.

Oh, and spend a week in Lake Como while I was at it.

To my shock, I was actually able to do most of all of that. I didn’t get a chance to visit the Furlan Marri showroom in Geneva and I wasn’t able to score a visit to the Oris factory in Hölstein but those were about the only things I think I had on my itinerary that I missed. After all, with travel, the break at Lake Como, and bouncing from one city to another, there were maybe three or four days in which I could accomplish all of those objectives.

I’m in love with Zurich. Geneva is nice, but really, you gotta stick to the Old Town area. Exploring the alleys and byways around the Vieille Ville - and especially around the Grande-Rue is stepping into a completely different world.

But it was Zurich that stole my heart. We stayed in the Niederdorf district and it was... sublime. Zurich itself is sublime; there’s no other way to describe it. Even at the peak of summer, it’s a city that manages to keep its cool. Geneva may be where watch-lovers flock to, but Zurich is where I left my heart.

Also, it was in Zurich that I had the best Chicken Tikka Kabab I’ve had since I left India more than 30 years ago. Go figure.

But enough about Zurich. Let’s talk about watch stuff.

You’ve seen this building in my last newsletter.

It’s an unassuming building in Biel, Switzerland. Inside it is a manufacturing facility with rows upon rows of CNC (Computer Numerical Control) machines in a neat, orderly fashion. Bars of solid metal like stainless steel and grade 2 titanium are fed into one end. Out of the other end come small parts like cases, bracelet links, bezels, and more. It’s a marvel of engineering that’s a far cry from the hand-operated tools and small analog machines you associate with Swiss watchmaking.

This is modern Swiss watchmaking, and I am here for it. It also is the the pathway to a problem that was well-articulated by a recent Hodinkie article on the M.A.D.Editions M.A.D.1S.

Loving watches is a democratic thing. Anyone can love watches. Owning watches is inherently the opposite.

On the same floor of building are the offices of a brand I’m sure many readers of this newsletter are familiar with: Formex. Here’s an interesting tidbit: the co-owner and CEO of Formex - Raphael Granito - is the son of the founder of Dexel. His personal office has two doors; one leads into the Formex atelier and offices, while the other leads into the Dexel side of the floor.

Most of the parts that go into Formex watches like the Reef and the Essence are manufactured on the floor below, in the Dexel factory. The relationship is not accidental; it’s a case of surprising vertical integration in an industry that is known more for not being all that vertical. As I realized in my conversation with James Mulvale from Farer a while back, the watchmaking industry in Switzerland is “a geographically spread-out assembly line that stretches across maybe a hundred or more miles..”

It’s also a demonstration of interconnectedness. The Swiss watchmaking world may seem insular to some, but even a casual glance under the hood shows that there’s a serious amount of interconnectedness. Look at Dexel’s website and you’ll see the logo of at least one company they make parts for that goes back to the 19th century.

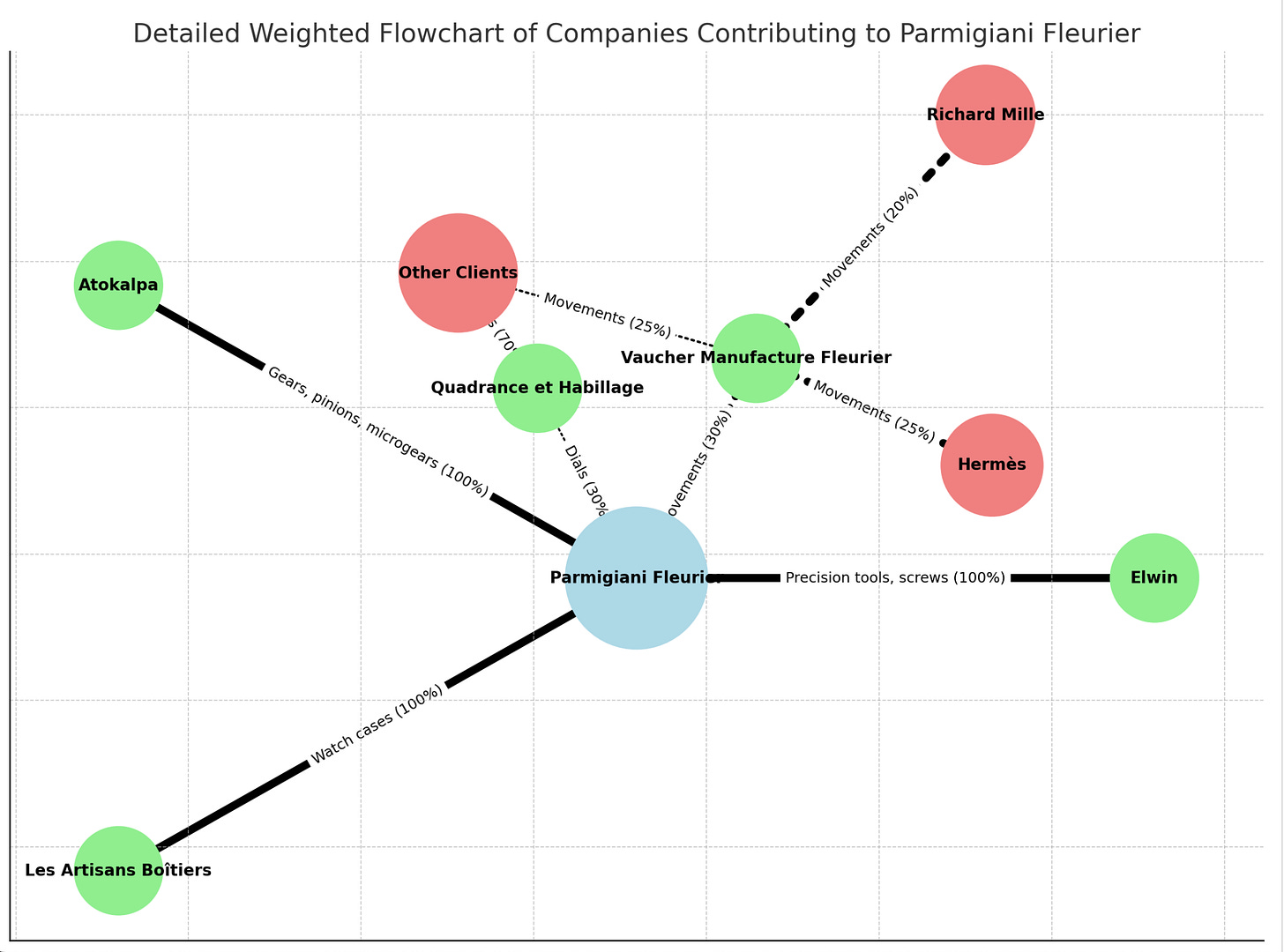

Another example: I was doing some research on Parmigiani Fleurier, the Swiss company whose watches (apart from being out of my price range) have found their way onto the wrists of kings and magnates. Even this venerated (if not old) Swiss brand operates in a web of interconnected companies and relationships.

I’ll have more on Formex (and another atelier I was fortunate enough to visit) in a future article. For now, let me say this: There are nuances to the world of Swiss watchmaking that I hadn’t quite grasped. This trip helped open my eyes to a lot of those nuances. The insularity is there, yes, but my particular corner of the world (independent and microbrands) is peeling that insularity back. What’s below is delightful and exciting and just plain fun.

Watch for Part 2 of this series and the deeper dives into the ateliers of Formex and Christopher Ward in the coming weeks.